PRODUCT

Drum Filter

Products Description

Fish farm aquaculture drum filter

Aquaculture wastewater scales of debris, residual waste most of main pollutants such as bait to suspended state exists in the form of large particles, in the treatment process shall, first of all, to keep clear of in time, and can reduce after process link to the load, and prevent the circulating water system components and pipeline jam. Commonly used mechanical filtration equipment has micro filter, pressure filter and sand filter, etc.

Product Feature

Notice:

The Drum filter size is determined by the treatment capacity, filtration accuracy, normally at the same capacity, more accuracy request more size.

In the practical engineering, the filter is widely applied, filtering effect is good. Microfiltration machine belongs to the mechanical and physical filtration method, have better application in the circulating water aquaculture water treatment effect, to a large number of plankton, quickly and effectively remove the water and the bait, excrement and other debris (fiber, granules, flakes, etc.). Microfiltration machine is reducing load biological treatment, is to improve the efficiency of water treatment, the most fast and economic method.

The Drum filter size is determined by the treatment capacity, filtration accuracy, normally at the same capacity, more accuracy request more size.

In the practical engineering, the filter is widely applied, filtering effect is good. Microfiltration machine belongs to the mechanical and physical filtration method, have better application in the circulating water aquaculture water treatment effect, to a large number of plankton, quickly and effectively remove the water and the bait, excrement and other debris (fiber, granules, flakes, etc.). Microfiltration machine is reducing load biological treatment, is to improve the efficiency of water treatment, the most fast and economic method.

Micro filter to remove solid suspension loop water function, the system of the biochemical filter also had a positive effect. Although the ammonia nitrogen conversion bacteria growth also need certain organic matter, but too much organic matter can cause digestive bacteria overgrowth, organic matter and ammonia nitrogen conversion bacteria in biofilm competition growth space, dissolved oxygen and nutrients. Organic matter digestion bacteria reproduction rate is much faster than ammonia nitrate bacteria, this will cause the breeding system of biological filter ammonia nitrogen removal rate is reduced, for example, when the biochemical oxygen demand (COD) and the ratio of ammonia nitrogen is greater than 2.7, ammonia nitrogen removal rate will drop by about 70%. Experiments show that using micro filter, biochemical filter inlet and outlet of the nitrite nitrogen concentration

mean difference is higher than 0.4 mg/L, do not use the micro filter of below average concentration of 0.1 mg/L.

Microfiltration machine is a rotating drum screen filter. Drum with the filter, when placed in water work drum, 2/5 filter submerged in water, waste water to be treated axially into the drum, by the screen outflow water impurities (fine suspended solids, fibers, pulp, etc.) Jibei trapped in the filter on the inner surface of the drum. When trapped in the filter impurities are brought to the upper part of the drum, is outside the screen backwash water will flow out into the sewage tank to achieve solid and liquid phases are separated by a timer or backwash liquid level sensor control. Filtered water is returned to the pool and reused. Microfiltration driven by hydraulic rotary machine, continuous automatic operation. 100m3 / h below the amount of processing equipment used throughout the entire food grade PP plastic, 100m3 / h or more with full 316L stainless steel, anti-corrosive, non-toxic and environmentally friendly. Mesh material is nylon, filtration accuracy: 30μ ~ 130μ, more than 95% removal rate of the solid particles, the number of revolutions microfiltration runtime is 1-3r / min, flow rate of 10-200m3 / h,

backwash pressure of 0.2 to 0.3 MPa, flushing water for the production of 0.5-1.0% water. Microfiltration machine installed in the drain ponds and below ground level, artesian water can enter, head loss of about 0.5 meters. Microfiltration: treated water, low operating cost; simple to install, easy filter replacement, less maintenance, long life; low power consumption, 100m3 / H work consumes only 0.55KW (Rotary motor)....

mean difference is higher than 0.4 mg/L, do not use the micro filter of below average concentration of 0.1 mg/L.

Microfiltration machine is a rotating drum screen filter. Drum with the filter, when placed in water work drum, 2/5 filter submerged in water, waste water to be treated axially into the drum, by the screen outflow water impurities (fine suspended solids, fibers, pulp, etc.) Jibei trapped in the filter on the inner surface of the drum. When trapped in the filter impurities are brought to the upper part of the drum, is outside the screen backwash water will flow out into the sewage tank to achieve solid and liquid phases are separated by a timer or backwash liquid level sensor control. Filtered water is returned to the pool and reused. Microfiltration driven by hydraulic rotary machine, continuous automatic operation. 100m3 / h below the amount of processing equipment used throughout the entire food grade PP plastic, 100m3 / h or more with full 316L stainless steel, anti-corrosive, non-toxic and environmentally friendly. Mesh material is nylon, filtration accuracy: 30μ ~ 130μ, more than 95% removal rate of the solid particles, the number of revolutions microfiltration runtime is 1-3r / min, flow rate of 10-200m3 / h,

backwash pressure of 0.2 to 0.3 MPa, flushing water for the production of 0.5-1.0% water. Microfiltration machine installed in the drain ponds and below ground level, artesian water can enter, head loss of about 0.5 meters. Microfiltration: treated water, low operating cost; simple to install, easy filter replacement, less maintenance, long life; low power consumption, 100m3 / H work consumes only 0.55KW (Rotary motor)....

Product packaging

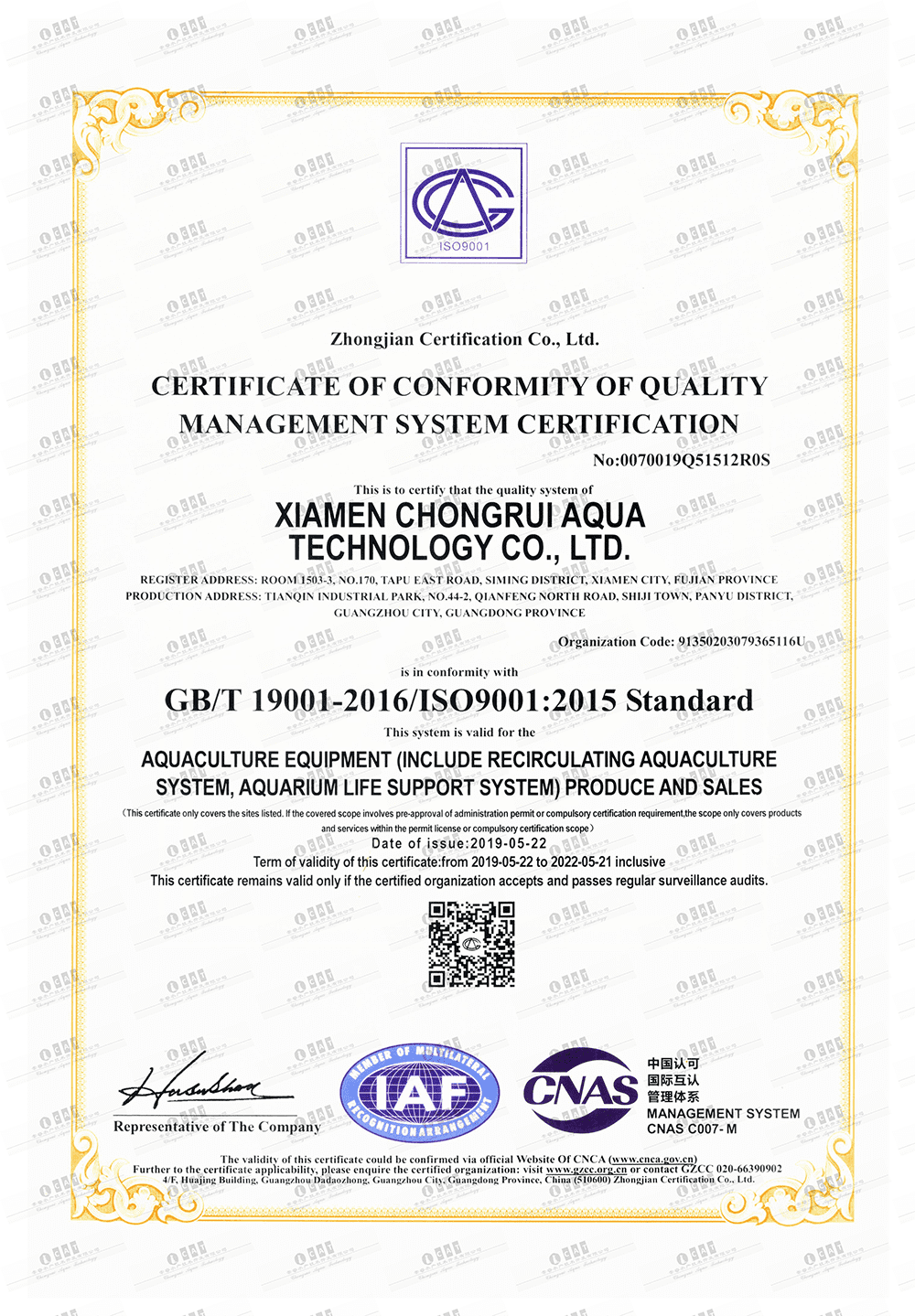

Why Choose Us

CAT-Chongrui Aqua Technology Co.,Ltd as the most professional whole RAS manufacture, designer and consult company, we offer the best quality Reliable goods to our honored customers that through the whole world, no matter the big Ocean Park like North Korea National Ocean park, Moscow Ocean Park etc. or the Shanghai Pudong Ocean park, Weihai Ocean Park, Chengdu Ocean Park, Chong Qing Ocean park, Luoyuan Ocean park, CAT people always spend 100% hard work try to offer customer the best goods and services.

We are professional and leading manufacturer over 20 years.

We produce and export high quality Recirculating Aquaculture System (RAS) which have a very high reputation among our customers.

Our RAS sells very well among our distributors in Europe, America, Mideast, Australia ,South Africa and Asia.

We are professional and leading manufacturer over 20 years.

We produce and export high quality Recirculating Aquaculture System (RAS) which have a very high reputation among our customers.

Our RAS sells very well among our distributors in Europe, America, Mideast, Australia ,South Africa and Asia.

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.