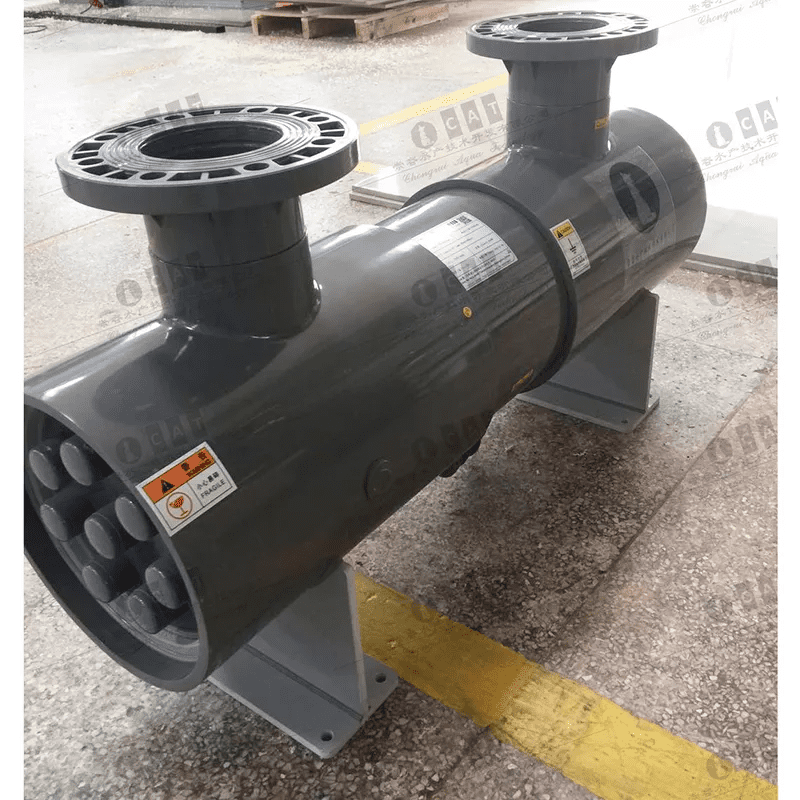

UV Sterilizer

Know What You Are Purchasing - All Quotes Are Not Equal

One of the primary jobs the sales and marketing team at CAT-AQUA has with relation to UltraViolet (UV) water treatment systems-is customer education. 'Why is that?' you may ask. Unfortunately, while the concept of UV treatment appears simple, the actual application of the technology is anything but. In fact, capable OEM suppliers take great care to ensure that the customer is able to meet their actual treatment needs, in all practical operational scenarios, today, and as the system ages.

In many cases a potential customer may notice that one quote for a UV product may come in at a significantly higher cost than that of another. Good news, right? Lowest bid wins!

Well, perhaps the company that provided the lowest bid wins, but the real loser may be the customer. In the UV treatment industry, as in many others, it is the hidden or unknown factors that can greatly impact whether your system actually delivers the intended UV dose, or 'treatment', or not. In fact, UV water treatment is such a complex technology that the USEPA and other regulatory bodies worldwide have standardized sizing and application regulations for municipal drinking water and waste water.

UV treatment - Basics you need to know about UV-C and UV Dose

As with any technology, fundamental knowledge is key to understanding the products you purchase. As a customer, being an expert in a given technology is not required. However, the more knowledge you have, the more likely you are to be a satisfied customer. To that end, it may be helpful to explain some of the key areas of interest with regards to UV water treatment.

UV Spectrum - There are four primary parts of the UV spectrum: UV-A and UV-B can make it through the earth's atmosphere. UV-C and UV Vacuum are blocked by the earth's atmosphere. In disinfection typically only UV-C is used.

UV Treatment - Applying the Photons

Now that you understand UV-C, UV Dose and log reduction, we will discuss UV system light sources. There are some key factors that you should be aware of when selecting a specific lamp type in a UV treatment system.

Mercury has been safely used in UV lamps for over a hundred years. In fact, it is very likely that the water you drink every day, whether it be from a tap or a bottle, was treated by a UV system. Mercury is used in lamps because the mercury emits photons, primarily at the 254nm wavelength (nm is short form for nanometer) when excited by an electrical discharge - and this 254nm emission is right near the peak of microbiological inactivation for most organisms of concern.

There are two families of mercury-based lamps used in disinfection - monochromatic lamps that emit primarily at 254nm, and polychromatic lamps that emit with a broad spectrum, where the usable disinfection wavelength range is from 220nm to 280nm. Low-pressure, low-pressure high-output and amalgam lamps are all considered monochromatic in output. Medium-pressure lamps are considered polychromatic.

Lamp efficiency is overlooked by many people, however, if electrical power consumption is important to you, you may want to consider this factor. Lamp efficiency is the ratio of the amount of UV-C output of the lamp, as compared to the electrical input. Efficiency can range from ~35 percent or more for some light sources, to as low as a few percent for others.